G.AL® Precision Cast Plates

When you can’t compromise on quality

G.AL® Precision Plates set the standard in:

- Thickness Tolerance

- Flatness

- Parallelism

- Surface Roughness

In addition to general dimensional precision, we focus on fundamental properties such as the plate’s physical, metallurgical, and technological characteristics.

The result?

Maximum precision—inside and out.

G.AL® Precision Plates (commonly known as aluminum cast tool and jig plates) are made from raw materials developed specifically to meet the GLEICH factory standard.

G.AL® Precision Plates:

G.AL® C250

Highest Precision, Extremely Low Tension G.AL® C250

G.AL® C330

Highest Precision, High Strength

G.AL® C330

Heat Treating

Each plate is individually heat-treated on-site with a fully customized process designed to bring out maximum performance. No other company treats plates this way, giving us the ability to control quality at every step.

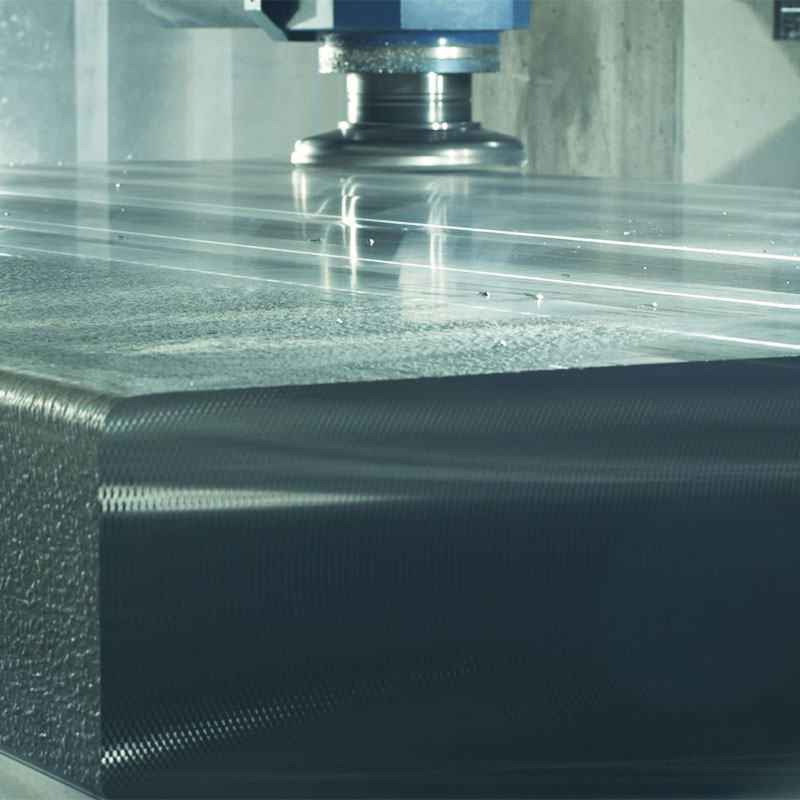

Milling

Once heat treatment is complete, state-of-the-art band saws are used to trim the plates without introducing internal stress, resulting in stress-relieved sawn plates. They offer a fine-grained, homogeneous microstructure and high strength values with no directional influence. This means properties remain consistent throughout the entire plate, unlike traditional rolled plates. We use stable portal milling machines with milling heads over 7 feet wide to achieve the precision, accuracy, and distinctive surface characteristics that define our G.AL® Precision Plates.

After milling, we inspect each plate for:

• Thickness and flatness tolerances

• Surface roughness

• Overall quality

A protective PVC film is applied to ensure the surface remains intact during handling and delivery.