G.AL® C210R

Versatility for Medium-

Strength Applications

Medium Strength Plate

Alloy: EN AW-5083 [AlMg4,5Mn0,7 – 3.3547]

Type of alloy: Non Heat-Treatable

Temper: O3

Surface: Sawn on All Sides, Roughness Ra <15 µm

- Low Stress

- Dimensional Stability

- Corrosion Resistance

- Available up to 43.3” Thick

- Sawn on All Sides

G.AL® C210R is the jack of all trades. It’s characterized by low-stress properties, dimensional stability, and excellent homogeneity consistant across the ingot. Made with Alloy EN AW-5083 (AlMg4.5Mn0.7), G.AL® C210R is incredibly corrosion-resistant and is well suited for technical anodizing. With slab thicknesses up to 43.3” and widths up to 86.0”, it’s ideal for large-scale projects.

Applications

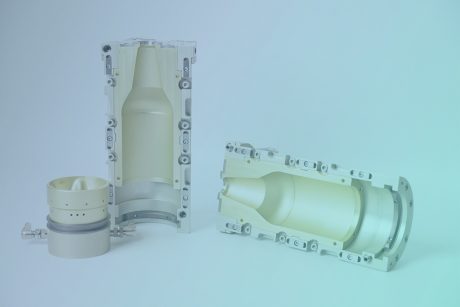

Mold Making

G.AL® C210R‘s excellent machinability makes it the perfect choice for deep drawing, foaming, casting molds, and prototype molds for plastic injection molding.

Semiconductors

Thanks to low microporosity and

great machinability, G.AL® C210R easily

withstands vacuums up to 10-7 mbar.

Optics

Manufacturers of optical devices and equipment appreciate G.AL® C210R’s anodizing abilities, providing functional and visually stunning surfaces.

Medical Technology

The low-stress properties of G.AL® C210R ensure distortion-free components, even with machining levels above 90%.

Food and Agriculture

G.AL® C210R is widely used in food and agricultural applications, it’s in compliance with food safety regulations (EN 602-2004)

Laser Technology

Outgassing is almost entirely eliminated, thanks to the low silicon content and homogeneous structure of G.AL® C210R

Components machined above 85-90% often pose production problems. G.AL® C210R‘s low stress allows for over 90% machining, resisting distortion and loss of structural integrity.