G.AL® C330R

High Strength

Form Stability

High Strength Sawn Plate

Alloy: EN AW-7021 [AlZn5,5Mg1,5]

Type of alloy: Heat-Treatable

Temper: Solution Heat Treated, Quenched & Artificially Aged, T79

Surface: Sawn on All Sides, Roughness Ra <15 µm

- Stress-Relieved

- High Strength and Hardness

- Available up to 18.9″ Thick

- Sawn on All Sides

The high strength aluminum plate G.AL® C330R is made from alloy EN AW 7021 (AlZn5.5Mg1.5) with material temper T79. It’s sawn on all sides and characterized by low-stress, high strength and high hardness. The uniform strength makes G.AL® C330R a great material choice in industrial and manufacturing sectors.

Applications

Tool Making

The strength of G.AL® C330R makes it ideal for highly-loaded components like tool changers (revolver magazine) for turning machines.

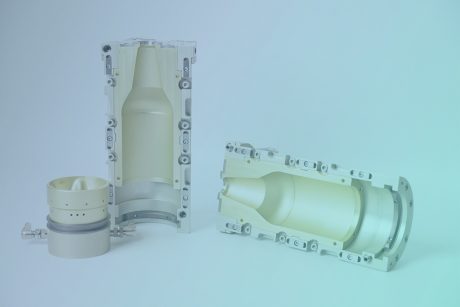

Mold Making

The high thermal conductivity of G.AL® C330R reduces cycle times in foaming, blowing, deep drawing, RIM, and injection molds (low and medium pressure).

Automation

In highly-loaded components like jigs and swivel devices, G.AL® C330R replaces rolled plates with risidual stress.

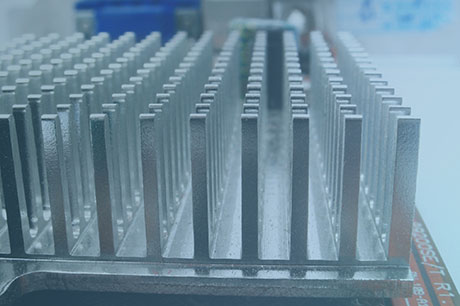

Mechanical and Special Machine Engineering

Easy machining and dimensional stability make G.AL® C330R a safe and efficient material for creating holders, clamping devices, and any other components requiring high degrees of machining.

Handling Machines

Preferably, tool and component carriers are made of low-stress and wear-resistant Aluminum materials. G.AL® C330R plates are a perfect choice.

Thermal Stress

High-strength aluminum alloys tend to experience irreversible structural changes and loose strength when operating in temperatures above 190 °F. G.AL® C330R can be used permanently at 250 °F, and for short periods (4 – 6 h) up to 280 °F without damage. The material can even withstand temperatures up to 320 °F for 1 – 2 h.

All high-alloyed materials are very sensitive to contact corrosion, especially when steel, copper, brass or bronze was previously used on the CNC machines. In most cases, the pH value is well above 8.5. To avoid contact corrosion, components should be taken off the machine immediately after machining and thoroughly cleaned and dried.