G.AL® C330 DYNAMIC

Specialized for

Highly Sensitive Applications

High Strength Plate

Alloy: EN AW 7021 [AlZn5,5Mg1,5]

Type of alloy: Heat-Treatable

Temper: Solution Heat Treated, Quenched, Artifically Aged, T79

Surface: Sawn on All Sides, Roughness Ra <15 µm

- Microporosity Free

- Diffusion Resistance

- High Strength

- High Hardness

- Excellent Elongation

- Easily Machined, Dampened, and Polished

- Ideal Under Dynamic Loads

G.AL® C330 DYNAMIC is an enhanced version of G.AL® C330R made from alloy EN AW 7021 (AlZn5.5Mg1.5). The special casting perameters, post processing, and multi step heat-treatment of G.AL® C330 DYNAMIC make it isotropic, free of microporosity, and gives it great stretching abilities.

Applications

Hydraulics

Microporosity prevents the use of conventional cast plates in hydraulics. The lack of micropores and the incredible stretching capabilities of G.AL® C330 DYNAMIC allow it to perform more highly than conventional cast plates, and rolled steel plates commonly used.

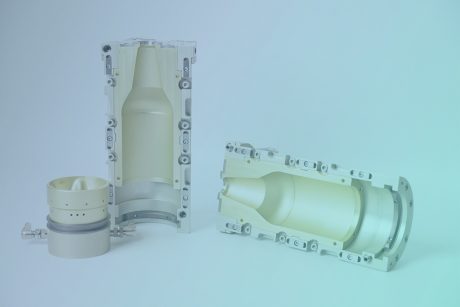

Mold Making

G.AL® C330 DYNAMIC outperforms traditional rolled plate pre-series injection molds in automotives (plastic: PP) EN AW 7010. Easily machined and polished, low stress, and isotropic properties allow G.AL® C330 DYNAMIC to shorten prep time by up to 40%, and extend mold life by up to 17%.

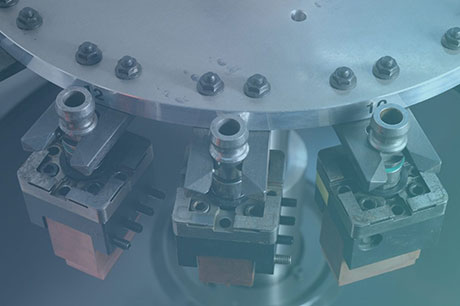

Drive Technology

Gearboxes for assembly lines, sliding units or actuating / clock units often need to absorb high forces with thin wall thicknesses. Commonly, machining of more than 90% is required. Machining at this level is difficult with rolled plates, but easily accomplished with G.AL® C330 DYNAMIC.

Mechanical and Special Machine Engineering

Tool carriers, force redirection devices (fork heads), bearing blocks, and other pieces are often made from distortion-prone rolled plates. Manufacturing these pieces from rolled plates can be costly and time-consuming. With G.AL® C330 DYNAMIC, designers have a material that combines low-stress with high strength and hardness values to give exceptional stretching.

Isotropic properties are essential in many industries, like hydraulics. G.AL® C330 DYNAMIC prevents faulty manufacturing caused by non-isotropic materials.