Expert Guide to Tool and Jig Plates

Having trouble deciding which material to use for tools and jigs?

We’re here to help!

Our expert guide to tool and jig plates compares the pros and cons of cast and rolled plates. We explain uses and advantages so you can choose material with confidence.

What are cast tool and jig plates?

Aluminum cast tool and jig plates (T&J) are brought to format (desired size) by sawing and precision machining. In contrast, rolled plates are brought to format by using force, rolling them until the desired thickness is reached.

The process of creating cast plates is inherently less stress inducing than creating rolled plates, meaning Tools and jigs made from cast plates are more dimensionally stable.

G.AL® C250 in alloy EN AW 5083 was developed specifically for tool and jig making. It’s considered the most, “relaxed” cast T&J plate on the market. Manufacturers prefer it because of the low stress, uniform stability, and precise flatness.

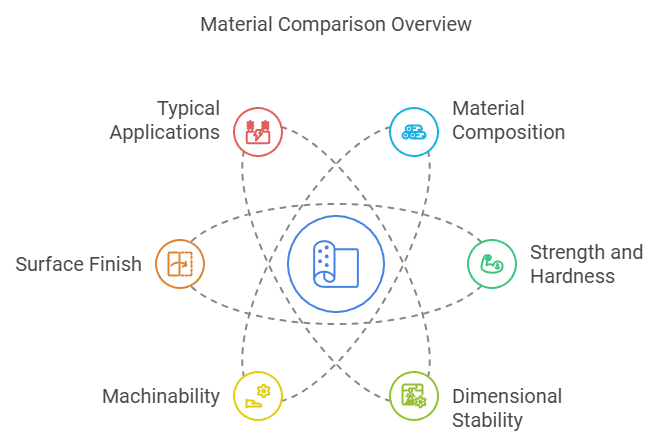

Comparing G.AL® C250 and 6061 T651

G.AL® C250 (5083 CT&J) and 6061 T651 aluminum are possible materials to produce machined pieces. Each option has pros for specific uses. Understanding how they’re different is important to choose the best one for you.

See our pdf comparison guide comparing the two materials.

1. Composition and Properties

G.AL® C250

- Made by sawing and precision machining aluminum slabs without introducing stress to the material.

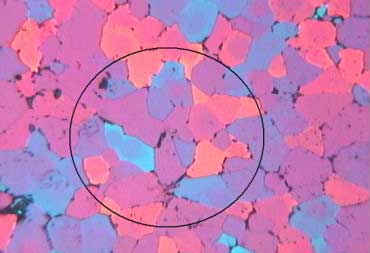

- Temper O3 (GLEICH Heat Treatment) causes the material to homogenize, giving us an isotropic (consistent) grain structure across the plate.

- Because the plates are so low stress, machining intricate pieces with precision and without warping the material is a breeze.

Homogeneous, isotropic G.AL® microstructure

6061 T651 Aluminum

- Heat-treated aluminum alloy with high tensile strength,

commonly used in structural applications - “T651” refers to the specific temper. This temper means the metal has been solution heat-treated and artificially aged to increase the hardness and stability

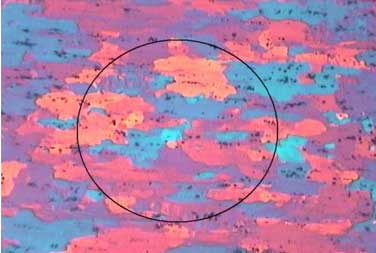

- Rolling process distorts the grain structure

- Mechanical values are not isotropic, no consistency across the plate.

Distorted, anisotropic rolled plate microstructure

2. Strength and Hardness

G.AL® C250

- Lower tensile strength (around 37 ksi) and hardness

(around 75 Brinell) than 6061 - Stability and low-stress makes C250 ideal when creating precise pieces that aren’t load-bearing.

6061 T651 Aluminum

- Stronger than G.AL® C250, tensile strength of around 45 ksi and hardness of 88 Brinell

- Better suited to structural integrity and load-bearing

3. Dimensional Stability and Machinability

G.AL® C250

Dimensional Stability

-

- Excellent dimensional stability, even under

heavy machining. - Ideal when warping resistance and precise measurements are required.

- Excellent dimensional stability, even under

- Machinability

- Easily machined

- Generally more forgiving, especially in high-precision machining

- More suited to inticate details

6061 T651 Aluminum

Dimensional Stability

-

- Less stable than C250

- Ideal when heavy load bearing is required.

- Machinability

- Decent machinability

- Residual stress can cause movement during milling and drilling

- High drop in strength from edge to center of 6061 directly causes higher tool wear and shorter component life

4. Surface Finish and Tolerance

G.AL® C250

- Precision milled surface finish

- Tight thickness tolerances (within ±0.005inches or better)

- Finish means minimal/no machining required if a precise, ready to use flat surface is required.

6061 T651 Aluminum

- Generally requires additional surface preparation, especially for tight tolerance applications

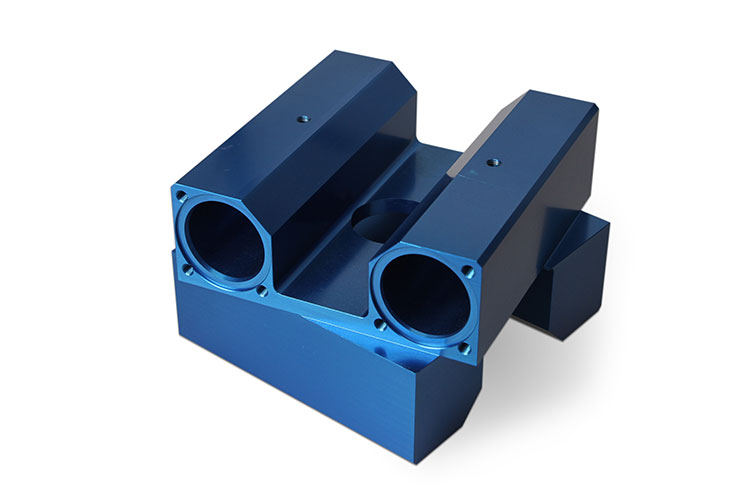

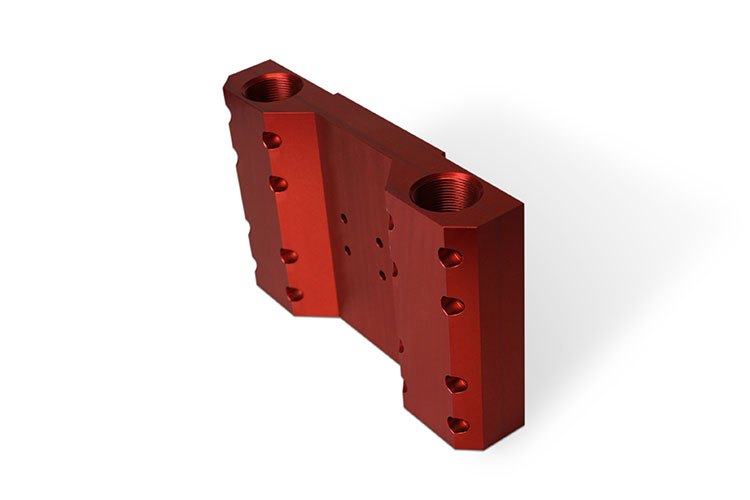

G.AL®, Anodized

G.AL®, Anodized

5. Typical Applications

G.AL® C250

Best suited for

-

- Precision Tooling

- Jigs

- Fixtures

- Stable Base Plates

- Molds

- Inspection Fixtures

6061 T651 Aluminum

Best suited to structural applications where strength and durability are prioritized, including

-

- Aerospace

- Construction

- Strong Bases

Conclusion

G.AL® C250

Choosing between aluminum G.AL® C250 and 6061 T651 depends on the specific needs of your project.

If stability, flatness, and low residual stress are critical, G.AL® C250 is the way to go.

For applications requiring strength and corrosion resistance, 6061 T651 is typically the better choice.

Questions?

Interested in our products?

Just want to say hi?

Connect below or send us an email at Sales@GLEICH-USA.com , we’re happy to help!

More Topics

5083 vs 6061 Aluminum

Comparing Properties, Strength, and Applications. Whether your project demands dimensional stability or structural strength, both 5083 and 6061 offer unique features to support a smoother production process.

Aluminum in Medical Technology

Aluminum in Medical Technology GLEICH's Role in Advanced Healthcare Solutions Aluminum plays a...

Understanding Aluminum Tempers

When working with aluminum alloys—especially in tooling, mold making, or aerospace applications—knowing the alloy’s temper is just as important as knowing its composition.