Proper Aluminum Storage

Best Practices for Preventing Aluminum Damage when storing Indoors or Outdoors

Storing aluminum the right way can be tricky, but don’t worry!

Unwanted corrosion can cause the material to become weak and brittle, making it unusable until recycled into new pieces.

In this guide, you’ll learn best practice storage tips for preventing expensive aluminum damage on slabs and cast plates and protecting their structures and properties.

The Importance of Storing Aluminum Correctly

Proper storage can prevent aluminum damage. Unwanted corrosion, condensation, and surface defects (especially in humid or fluctuating environments) can all occur when stored incorrectly. Improper storage can lead to damaging corrosion, discoloration, and degradation (especially when exposed to moisture or contaminants). While all aluminum is at risk, certain alloys require extra care. Fortunately, with the right techniques, preventing aluminum damage and storing it safely is simple.

Quality Check

Aluminum Inspection: Promptly inspect materials for signs of damage or corrosion risks

Corrosion is the gradual damage of metal caused by chemical reactions with moisture, air, or other environmental factors. Minerals often found in rainwater, humidity, or other types of moisture can accelerate this process.

Sometimes, corrosion is an advantage when using aluminum. (We have an article about it HERE) In controlled conditions, corrosion can create a protective oxide layer and strengthen the material. However, when left to the elements, corrosion can ruin the material’s surface or alter its structural properties.

To prevent unwanted corrosion, always check for transport damage. Tears or holes in the protective film can cause rainwater, humidity, or other contaminants to reach the surface. Even if the protective film is intact, condensation can form between the aluminum layers and beneath the outer packaging. It’s important to inspect all packaging or protective materials before storing.

Any water on the material should be cleaned off immediately. We recommend using clean, soft, dry cloths to wipe off moisture, and finishing with a light amount of warm compressed air, if possible.

Moist intermediate layers and packaging must be removed. Band rollers and coils should also be dried. In certain circumstances, they may require replacement packaging as well.

Indoor Storage

Indoor Aluminum Storage Requirements: Control Humidity and Temperature

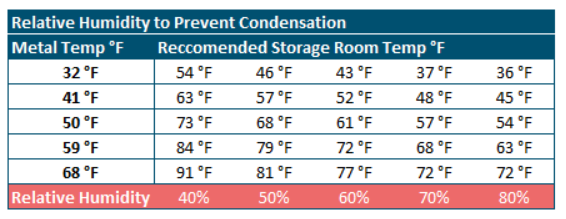

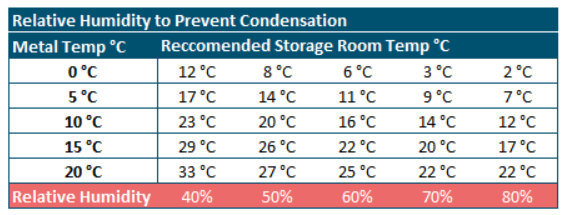

Be mindful of humidity, room temperature, and the metal’s temperature to prevent condensation. The storage room temperature should closely match the temperature of the processing environment. Before material transfer, aluminum can safely withstand lower temperatures if the relative humidity is controlled and room temperature remains stable.

If these conditions can’t be met, we recommend intermediate storage using appropriate spacers for airflow and to prevent condensation. It’s also a good idea to preheat the product before final storage.

When storing aluminum slabs for long periods, any specialized or sensitive surfaces can be protected by applying corrosion protection oil. Aluminum semi-finished products should not be exposed to other stored materials, metals, cement flooring, cleaning products, or stone walls.

Outdoor Storage

Temporary Outdoor Aluminum Storage: Protecting from the elements.

Sometimes, temporary outdoor storage is necessary, such as during construction. When storing outdoors, the following steps can prevent moisture from interfering with the surfaces:

- Prepare dry underlays (cover used wood planks with plastic strips)

- Avoid contact with lime, mortar, or other materials

- Cover aluminum immediately (heavy duty plastic tarps are recommended)

- Inspect daily (especially in high humidity)

Storage Conditions To Prevent Aluminum Damage

- Inspect Immediately

- Avoid Moisture

- Keep Temperature Stable

- Lower humidity, when possible

- Protect from the elements

Need help with aluminum storage solutions? Our team of experts is happy to help!

More Topics

Electrochemical Aluminum Polishing

Electrochemical aluminum polishing is also known as electrolytic polishing, electrolytic smoothing, electrolytic brightening, or electropolishing.

5083 vs 6061 Aluminum

Comparing Properties, Strength, and Applications. Whether your project demands dimensional stability or structural strength, both 5083 and 6061 offer unique features to support a smoother production process.

Aluminum in Medical Technology

Aluminum in Medical Technology GLEICH's Role in Advanced Healthcare Solutions Aluminum plays a...