G.AL® C210R

Versatility for Medium-Strength

Applications

Medium Strength Plate

Alloy: EN AW-5083 [AlMg4,5Mn0,7 – 3.3547]

Type of alloy: Non Heat-Treatable

Temper: O3

Surface: Sawn on All Sides, Roughness Ra <15 µm

- Low Stress

- Dimensional Stability

- Corrosion Resistance

- Available in thicknesses up to 43.3”

- Sawn on All Sides

G.AL® C210R is the jack of all trades. It’s characterized by low-stress properties, dimensional stability, and excellent homogeneity consistant across the ingot. Made with Alloy EN AW-5083 (AlMg4.5Mn0.7), G.AL® C210R is incredibly corrosion-resistant and is well suited for technical anodizing. With slab thicknesses up to 43.3” and widths up to 86.0”, it’s ideal for large-scale projects.

Applications

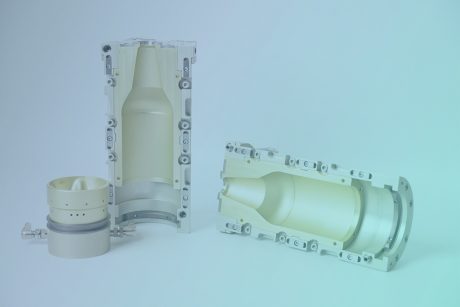

Mold making

G.AL® C210R‘s excellent machinability makes it the perfect choice for deep drawing, foaming, casting molds, and prototype molds for plastic injection molding.

Semiconductor industry

Thanks to low micro porosity and great machinability, G.AL® C210R easily withstands vacuums up to 10-7 mbar.

Optics

Manufacturers of optical devices and equipment appreciate G.AL® C210R’s anodizing abilities, providing functional and visually stunning surfaces.

Medical Technology

The low-stress properties of G.AL® C210R ensure distortion-free components, even with machining levels above 90%.

Food and Agriculture

G.AL® C210R is widely used in food and agricultural applications, it’s in compliance with food safety regulations (EN 602-2004)

Laser Technology

Outgassing is almost entirely eliminated, thanks to the low silicon content and homogeneous structure of G.AL® C210R

Components machined above 85-90% often pose production problems. G.AL® C210R‘s low stress allows for over 90% machining, resisting distortion and loss of structural integrity.