Heat Treating Aluminum

GLEICH Aluminum is one of the few aluminum cast plates manufacturers in the world with an in-house heat treatment facility.

But what actually happens during the heat treatment process and why it is necessary?

When we receive rolling ingots, we send them to our on-site heat treatment facility. Heat treating aluminum relieves internal stress and allows the aluminum alloy to perform at its fullest potential.

What is Heat Treatment?

Aluminum heat treatment is a controlled thermal process applied to aluminum alloys to alter their physical and mechanical properties (such as strength, hardness, ductility, toughness, and corrosion resistance) by changing the internal microstructure. These changes are typically done by a sequence of heating, soaking, and controlled cooling operations.

There are many different ways to heat-treat aluminum. At GLEICH, we do things a little differently.

Why is Heat Treating Aluminum Important?

The goal of heat treatment is efficiently producing great results without wasting resources. To do this correctly, you must first understand the processes, the properties of the raw material, and have clearly defined goals.

Aluminum products are often treated in furnaces designed for steel, which melts at a much higher point than aluminum. Treating aluminum in an inadequate machine can cause the material to lose strength or undo the advantages the alloy can provide. For example, temperature differences of 85-120 °F (30-50 °C) are hardly noticeable when treating steel. However, temperature fluctuations of more than 50 °F (10 °C) can cause significant structural damage or change the alloy properties.

Heat Treating Processes

Heat treatment processes play an important role when using aluminum. Rolling bars are almost exclusively treated in large quantities in gas-fired bogie hearths or bell furnaces.

This leads to a labor-intensive process when trying to control or maintain a consistent temperature throughout. Usually, this means that heat fluctuation is unavoidable and the material suffers. The resulting residual stress and uneven strength negatively affect the finished product.

Heat Treating GLEICH

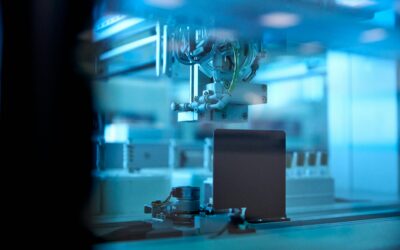

At GLEICH, heat treatment is performed using a unique, energy-efficient approach. The entire process controlled and carried out automatically in electrically heated furnaces. Cooling takes place in specially designed heat transfer furnaces, where bars undergoing treatment are cooled to precise measurements. This controlled temperature reduction ensures consistent quality and significantly reduces our energy consumption.

More Topics

Aluminum in Medical Technology

Aluminum in Medical Technology GLEICH's Role in Advanced Healthcare Solutions Aluminum plays a...

Understanding Aluminum Tempers

Understanding aluminum tempers like T6, T651, and T7351 how they affect strength, machinability, and corrosion resistance. Visual charts…

Classifying Wrought Aluminium Alloys

Classifying wrought aluminium alloys using EN and AA standards. We explain alloy series, designations, and the key differences between alloys