Electrochemical

Aluminum Polishing

Electrochemical aluminum polishing is also known as electrolytic polishing, electrolytic smoothing, electrolytic brightening, or electropolishing.

Electrochemical aluminum polishing eliminates surface defects and impurities, producing smooth, clean parts ready for high-performance use.

What Is Electrochemical Polishing?

Electrochemical polishing (ECP), also known as electropolishing, is a precise surface-finishing process used to smooth and brighten metal surfaces through anodic dissolution. Unlike traditional mechanical polishing methods, ECP removes material without inducing thermal or mechanical stress. This makes ECP ideal for high-spec use in aerospace, medical devices, semiconductors, and food processing.

Electropolishing is classified under DIN 8580 as a metal removal process. It is particularly effective at producing clean, smooth, corrosion-resistant finishes.

How Electrochemical Polishing Works

In the electrochemical process, components are connected anodically and immersed in a material-specific electrolyte. For electrochemical aluminum polishing, the electrolyte typically contains phosphoric acid, sulfuric acid, water, and other additives like polyethylene glycol.

The electrolyte is configured as an immersion bath with temperature control (heating, cooling) and circulation systems. A direct electric current is applied to the bath, causing aluminum to dissolve evenly. Raised or rough areas dissolve faster, resulting in a smoother, shinier finish. This process dissolves both macro and micro imperfections, smoothing the surface through macroscopic removal (which flattens and smooths) and microscopic/nanoscopic removal (which produces a bright, glossy finish).

Why Use Electrochemical Polishing for Aluminum?

Electrochemically polished aluminum surfaces have multiple advantages over mechanically polished ones. Key performance characteristics of ECP surfaces include:

• Uniform, smooth, and shiny surfaces

• Improved corrosion resistance

• Reduced friction and wear, extending component life

• Enhanced cleaning, best for sterile environments

• Lower outgassing, required in cleanrooms and vacuum systems

• Metallic purity and chemical passivity

• Improved fluid dynamics in tubing and channels

• Micro- and macro-deburring

• Enhanced post-anodizing aesthetics

These properties make ECP-treated aluminum ideal for industries where surface cleanliness, corrosion resistance, and appearance are critical.

Industries Served

Electropolishing offers advantages across many industries. Below are examples of sectors and components where electrochemical polishing is commonly used.

Medical Technology

Dialysis pump housings, blister punches, surgical tools

Semiconductors & Electronics

Printed circuit boards, vacuum parts, cleanroom equipment

Aerospace & Defense Systems

Impellers, guide vanes, fly-by-wire components

Chemicals & Pharmaceuticals

Pipes, valves, tanks, actuators

Food & Beverage

Molds, extruders, transfer devices

Additive Manufacturing & Mold Making

Molding tools, deep-drawing forms, precision surfaces

Best Aluminum Alloys for Electropolishing

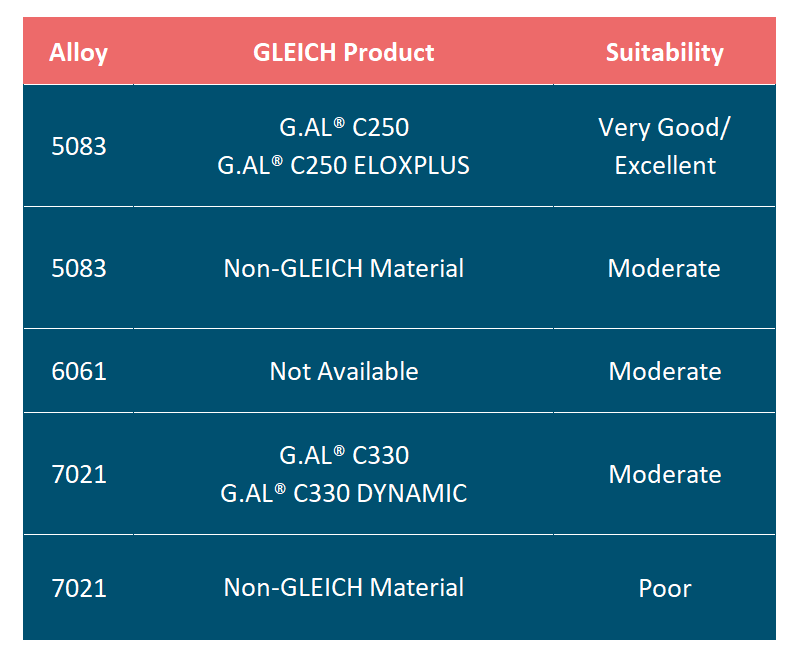

Not all aluminum alloys polish equally well. Alloys with high silicon content (greater than 1%) typically result in reduced gloss. Parts with grain microstructures larger than 130 µm can cause marbling.

For best results, homogenized cast aluminum with a fine, uniform grain structure is preferred. ECP performance can vary significantly based on alloy purity, grain structure, and stress relief. As a reference, we have added a guide comparing GLEICH material to commonly available, non-precision material.

*G.AL® is a registered trademark of GLEICH Aluminum GmbH, Kaltenkirchen, Germany.

GLEICH Aluminum Products for Electropolishing

GLEICH offers high-performance cast aluminum plates and alloys specifically engineered for electropolishing, including:

G.AL® C250 ELOXPLUS – Polishes and anodizes excellently

G.AL® C210 DYNAMIC – Outstanding surface consistency and machinability

G.AL® C330 DYNAMIC – Optimized for strength, machinability, provides moderate gloss finish

Contact our team of aluminum experts for assistance in choosing the right alloy for your project.

Electrochemical Aluminum Polishing: Step-by-Step

The following recommendations are intended to serve as general guidelines.

For safe, personalized instructions, please contact our team of aluminum experts.

1. Pre-Treatment

Pre-treatment is used to remove oils, greases, oxides, and contaminants that could impair uniform current flow when electropolishing. More than 75% of defective electropolishing results stem from inadequate cleaning. The electrochemical polishing process involves pre-treatment to clean and prepare the surface, electrochemical polishing to achieve the desired finish, and post-treatment to neutralize, rinse, and protect the component.

Alkaline bath

To degrease and clean plates for processing.

For Cast Plates:

Concentration: max. 15%

Temperature: 160-175 °F, 70–80 °C

Immersion time: 5 minutes at most

For rolled or forged aluminum:

Concentration: ~40%

Temperature: 160-190 °F, 70–90 °C

Immerse for at least 5 minutes (up to 15 minutes for best results)

Rinsing with industrial water

Remove all cleaning residue from components as soon as possible by rinsing and drying with warm, compressed air (if available).

Pickling

Pickling is a chemical treatment that removes oxides, impurities, and the natural oxide layer from the metal surface. By stripping away these layers, pickling ensures uniform current flow during electropolishing and prepares the aluminum for a smooth, consistent finish.

For Cast Plates:

Temp: 140-195 °F, 60–90 °C

Time: 45 seconds at most

For Rolled or Forged Material:

Temp: 140-195 °F, 60–90 °C

Time: At least 1 minute, ideally 3 minutes

Final rinse

Removes any residue from the pickling process.

2. Electrochemical Polishing

Surface polish quality results depend on the material state and alloy elements, particularly the silicon content.

Pure aluminum gives the best polish, but generally alloys with less than 1% silicon content polish well.

Electrolyte composition:

- Approximately 55% phosphoric acid / 35% sulfuric acid by weight

- Operating Temperature: 120-175 °F, 50–80 °C

- Current Density: 0.05–0.55 A/cm²

- Material Removal Rate: 15–60 µm/min

- Surface Finish: Up to Ra ~0.2 µm

3. Post-Treatment and Finishing

Post-treatment ensures that all acidic residues are removed, surfaces are thoroughly dried, and components are protected from staining or damage during storage and handling.

- De-acidification in diluted sulfuric acid to neutralize and remove electrolyte residue

- Temperature: Approximately 60-70 °F, 15–20 °C

- Time: 20–30 seconds

- 1-step rinse with tap water

- Remove any sulfuric acid residue, dry thoroughly

- 1-step rinse with demineralized water to prevent spotting. Remove any moisture and dry thoroughly

- Drying:

Use pure compressed air to remove water from all cavities, threads, or holes. We recommend using warm/hot air to finish. If dried properly, this step prevents material staining.

- Packaging:

To avoid condensation, parts must cool to room temperature before packing. To prevent surface marks, avoid using foam or bubble wrap.

Design and Manufacturing Tips

Best Practices for Ensuring Quality in Electrochemically Polished Aluminum

Design Considerations

Design oversights account for less than 4% of all ECP surface defects, but when they occur—especially in high-volume production—they can be costly.

To prevent surface defects:

- Avoid tight corners and inaccessible gaps

- Include vent holes in hollow parts

- Ensure wall thickness allows uniform current flow

- Consider material removal in fit tolerances

Manufacturing Precautions

Approximately 20% of ECP defects originate from machining operations, making it essential to follow proper practices during and after machining to maintain surface integrity.

To reduce the risk of defects:

- Always remove residual coolant or contaminants quickly to avoid pitting

- Clean components thoroughly between different metalworking operations to prevent pre-corrosion

- Use coolants with the correct pH and remove parts from the machine as soon as possible after machining

Work with GLEICH USA

As a leading supplier of high-performance aluminum products, GLEICH USA offers material solutions designed for electrochemical aluminum polishing and beyond.

Contact us today to speak with an aluminum expert and get recommendations for your project.

More Topics

5083 vs 6061 Aluminum

Comparing Properties, Strength, and Applications. Whether your project demands dimensional stability or structural strength, both 5083 and 6061 offer unique features to support a smoother production process.

Aluminum in Medical Technology

Aluminum in Medical Technology GLEICH's Role in Advanced Healthcare Solutions Aluminum plays a...

Understanding Aluminum Tempers

When working with aluminum alloys—especially in tooling, mold making, or aerospace applications—knowing the alloy’s temper is just as important as knowing its composition.