5083 vs 6061 Aluminum

Comparing Properties, Strength, and Applications

Whether your project demands dimensional stability or structural strength, both 5083 and 6061 offer unique features to support a smoother production process.

Where to Begin:

When choosing the right aluminum for precision-machined parts, two options that stand out are 5083 and 6061-T651. Each alloy has its benefits and limitations depending on the application. Understanding their properties is key to making an informed decision.

Common Cast Aluminum Tooling Plates

For comparison, we’ve listed a reference guide below including popular name-brand 5083 aluminum plates and their properties.

All plates referenced are stress-relieved, precision-milled, optimized for machining, and advertise flatness tolerances of ±0.0005 inches per foot.

| Product Name | Base Alloy | Tensile Strength | Brinell Hardness (HBW) |

| G.AL® C250 (by GLEICH)* | 5083, temper O3 |

~37 ksi |

~75 |

| Mic 6 (by Alcoa)* | Similar to 5083 | ~27-30 ksi | ~65-75 |

| ATP-5 (by Vista Metals)* | Similar to 5083 | ~30 ksi | ~70 |

| Alca 5 (by PCP)* | Similar to 5083 | ~38 ksi | ~70-75 |

| K100-S (by Alpase)* | Similar to 5083 | ~30-35 ksi | ~70 |

*G.AL® C250, MIC 6®, ATP-5™, ALCA 5®, and K100-S™ are registered or trademarked brand names of their respective manufacturers. G.AL® C250 is owned by the GLEICH Group, which has no affiliation with any other brands listed in this comparison.

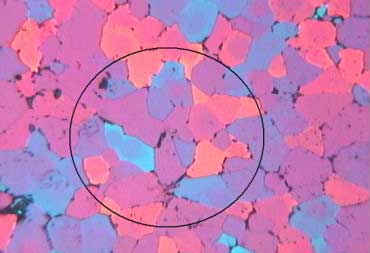

Material Composition and Grain Structure: 5083 vs 6061

5083 – G.AL® C250

G.AL® C250 is GLEICH’s 5083 plate. It is manufactured by sawing and precision-machining cast aluminum slabs without altering the natural grain structure. This process results in a homogeneous, isotropic grain structure—meaning it exhibits consistent mechanical properties in all directions (length, width, and thickness).

To enhance dimensional stability, GLEICH applies a proprietary heat treatment that sets the G.AL® C250 plate to temper O3, effectively relieving internal stresses.

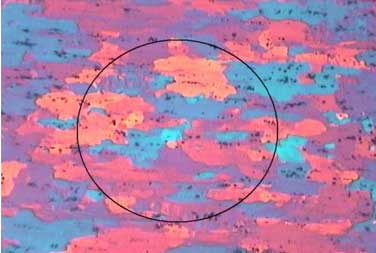

6061-T651

6061-T651 is a rolled, heat-treated aluminum alloy commonly used for structural components. The “T651” temper indicates that it’s been solution heat-treated, stress-relieved, and artificially aged, but the rolling process causes directional grain flow, creating an anisotropic grain structure. This grain structure leads to variable mechanical performance across the plate, which can impact stability and cause problems for precision applications.

5083 – Uniform, stress-relieved grain

6061-T651 – Stressed, distorted grain

Strength and Hardness

5083 has a slightly lower tensile strength (around 37 ksi) and hardness (around 75 Brinell) than 6061. While not as strong, the dimensional stability of 5083 makes it better suited for applications where raw strength is less of a priority.

6061-T651 is stronger than 5083, with a tensile strength around 45 ksi and a hardness of 88 Brinell. It is better suited for load-bearing applications requiring high structural integrity.

Dimensional Stability and Machinability

Dimensional Stability

5083 maintains excellent flatness, even under extensive machining. It’s ideal for high-tolerance applications such as inspection fixtures, jigs, and mold bases. In contrast, the internal stresses in 6061 mean it often requires additional machining steps to meet the same tolerances.

Machinability

Both materials are machinable, but 5083 tends to be more forgiving and stable (even in high-precision operations). 6061-T651 is known to shift during milling and drilling. The stresses mean that its strength can vary greatly from the edges to the centers of components. This high drop in strength causes uneven tool wear, making it less ideal for high-precision pieces.

Surface Finish, Tolerance, and Corrosion Resistance

G.AL® C250 comes with a milled, ready-to-use finish. Its surface is milled to tight thickness tolerances within ±0.005 inches per foot, or better. Alloy 5083 is known for its excellent corrosion resistance, with or without anodizing, even in saltwater.

6061-T651 typically requires additional surface prep, especially for high-tolerance work. It offers good corrosion resistance that can be improved by anodizing. It is not recommended for marine use due to its poor resistance to saltwater.

Common Uses

G.AL® C250/5083 is best suited for precision tooling, jigs, fixtures, and bases where stability, accuracy, and flatness are essential. It’s the go-to option for projects such as molds, inspection fixtures, and base plates.

6061-T651 is best for structural or load-bearing uses where strength and durability are prioritized, including aerospace and construction parts.

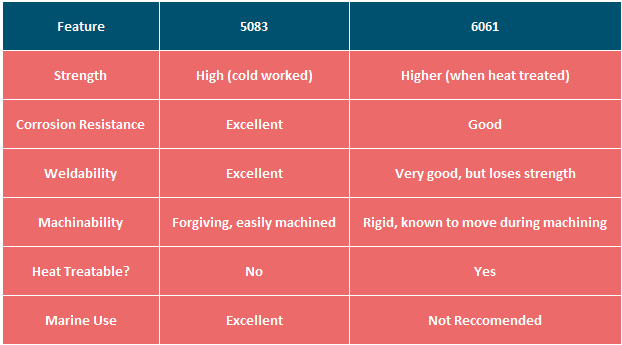

Summary

Different types of aluminum offer distinct advantages for different applications. 5083 and 6061-T651 each offer unique benefits depending on the project needs. If stability, flatness, low stress, and minimal distortion are critical, 5083 is often the best choice.

If your focus is on load-bearing strength and general machinability, 6061-T651 provides solid performance.

We’ve put together a reference guide below for a quick comparison.

Need Help Choosing the Right Aluminum?

Our Product Selection Tool (click HERE to view) helps match your needs to the best material.

Still unsure? Talk to one of our aluminum experts today!

More Topics

Electrochemical Aluminum Polishing

Electrochemical aluminum polishing, also known as electropolishing, delivers smooth, corrosion-resistant surfaces by removing imperfections at both the macro and micro levels. Ideal for aerospace, medical, semiconductor, and precision manufacturing applications, this process enhances performance, extends component life, and ensures consistent results where precision matters most.

Aluminum in Medical Technology

Using Aluminum in Medical Technology. FDA-compliant & corrosion-resistant. Engineered for medical technology, vacuums, and thermal uses.

Understanding Aluminum Tempers

Understanding aluminum tempers like T6, T651, and T7351 how they affect strength, machinability, and corrosion resistance. Visual charts…