Aluminum In Cleanrooms

Using Aluminum In Sterile Environments

Cleanroom technology is essential for the operation of key industries worldwide. Cleanrooms are essential for safely manufacturing critical products. The materials used in cleanrooms must have certain qualities to keep the environment sterile.

Indispensable Technology

Pharmaceuticals, medical equipment, biotechnology, food, cosmetics, microelectronics, micromechanics, automotive pieces, and hundreds of other industries use cleanrooms to develop and manufacture their products. Without sterile conditions, nobody could trust the quality of their products. From life-saving medications and microscopic circuit boards to preventing cross-contamination in food manufacturing, cleanrooms are essential to modern industry.

What Is a Cleanroom?

The term “cleanroom” refers to an enclosed area within an assembly unit.

It is vital that some products (medications, food, medical equipment, etc.) stay free of contamination. If exposed to foreign particles, the reaction, function, or properties of the products can’t be trusted. There are strict requirements for how many elemental and molecular particles are allowed in the cleanroom throughout the entire manufacturing and handling process. Internationally recognized cleanroom classifications, such as DIN EN ISO 14644-1 and Good Manufacturing Practice (GMP), strictly define the particle levels allowed in these environments..

For required cleanroom class specifications, the guidelines according to VDA 2083 also apply.

DIN EN ISO 14644-1 conditions are the minimum required when manufacturing or handling:

• Medical devices

• Optics and lasers

• Microelectronics

• Micromechanics

• Automotive parts

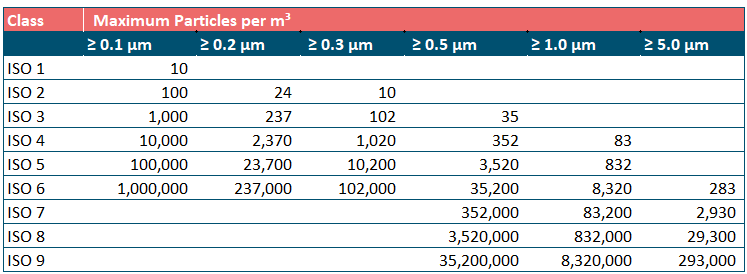

DIN EN ISO 14644-1 – Maximum Permissible Concentration (Particles per m³)

Depending on particle size (µm)

In addition to DIN EN ISO 14644-1, the EU-GMP classes also apply in:

Pharmaceuticals

Biotechnology

Medical technology

Food and Cosmetics

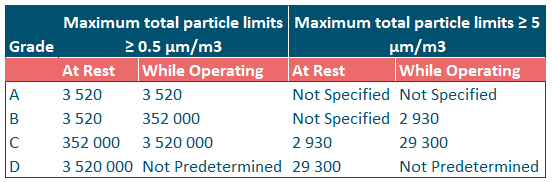

EU-GMP Class – Maximum Permissible Number of Particles per m³ Atmosphere

For more information about cleanrooms, please visit ISO 14644-1 HERE

Further Requirements

ISO Class 5 roughly corresponds to GMP Class ‘A’ and must meet particularly high purity standards. These regulations specify the maximum allowable number of microscopic particles in the air to remain compliant with standards.

This applies to both particulate and molecular contamination. To meet the cleanliness classes and product quality, the machinery and materials used are even more important.

Materials must be highly resistant to solvents, experience extremely low outgassing, and have exceptionally smooth surfaces. The material must also meet structural requirements (like strength).

Not all cleanroom components and assemblies can be made from stainless steel, which is generally the preferred material. This is where aluminum comes in.

Which Materials Meet these Standards?

Minimizing Molecular Contamination

To minimize contamination risks, alloying elements and “impurities” in aluminum semi-finished products can’t exceed the following limits:

(values shown as % by mass)

* Cu = 0.1%

* Mn = 0.8%

* Zn = 0.2%

* Pb = 0.05%

* Si = 0.3% (important in laser technology)

Lower concentrations of these alloying elements result in reduced strength and hardness of the aluminum. Alloys that fit these descriptions are rare, so the best option is to use a naturally hard alloy like EN AW 5083 (AlMg4.5Mn0.7)

EN AW 5083 complies with RoHS and REACH directives and is approved according to DIN EN 602 for food contact applications.

These G.AL® products fit the bill:

• G.AL® C210R

• G.AL® C210 DYNAMIC

• G.AL® C250

• G.AL® C250 ELOXPLUS

The permissible alloying elements under DIN EN 573-3 are restricted in these products by GLEICH’s in-house standard and do not reach the listed values, in some cases falling significantly below them.

These restrictions ensure maximum material quality and reproducibility of final products.

G.AL® C210 DYNAMIC has a highly compact structure, is completely free from microporosity, diffusion-tight, and passes the (helium) vacuum leak test at min. 10⁻¹² mbar. The permeability of this product, measured with a Förster probe after machining, is 1.000.

The more compact and homogeneous a material is, the more uniformly its hardness is distributed across the metal structure. This drastically reduces the risk of grain components being crushed or shifted during machining, lowers the risk of foreign substances diffusing into the metal, and increases abrasion resistance.

Aluminum semi-finished products with a highly compact and completely micropore-free structure throughout their volume provide the best conditions for excellent work results.

Only the cast plate G.AL® C210 DYNAMIC possesses these structural properties.

If complete freedom from microporosity and extreme compactness are not absolutely necessary, the precision cast plates G.AL® C250 or G.AL® C250 ELOXPLUS can also be used.

Minimizing Outgassing

Microporosity, surface cracks, or imperfections of any size can absorb liquid and gaseous contaminants. These substances can interfere with cleanroom purity, leading to contamination through outgassing. Avoiding imperfections is key to preventing outgassing. The best way to avoid these imperfections is to use material that is easily machined and milled, and that has little to no microporosity (depending on the application). Keep in mind that even slight temperature fluctuations can cause stress among materials, causing them to release these contaminants.

Generally, engineers choose stainless steel over aluminum because it’s assumed to be less prone to outgassing.

Tests conducted by our customers have shown that G.AL® C210 DYNAMIC is the only aluminum that exhibits outgassing as low as (if not lower than) stainless steel.

Corrosion, Solvent, and Cleaning Agent Resistance

EN AW 5083’s homogeneity is made to resist corrosion.

The level of metal homogenization is dependent mostly upon the level and accuracy of the heat treatment process. For best results, GLEICH uses electrically heated furnaces, where each ingot is processed individually. No other company in the world heat treats aluminum this way, and every G.AL® product receives this treatment.

Treating or coating the material’s surface enhances its resistance to degradation and maintains a clean appearance. Treating the material helps ensure that even the most aggressive cleaning agents can’t penetrate the surface.

Abrasion Resistance

Abrasion resistance directly correlates to surface hardness. Aluminum is generally considered a relatively soft metal; for instance, EN AW 5083 has a Brinell hardness (HBW) of approximately 65–75.

Aluminum hardness is primarily a physical property and secondly a mechanical one. Many engineers choose to enhance surface hardness by anodizing or chemically processing.

For anodizing, the more homogeneous and compact the material, the more evenly the anodic oxide layer and surface hardness are formed and the better its abrasion resistance.

If you need to create a clean room without the risk of outgassing, G.AL® C210 DYNAMIC and G.AL® C250 ELOXPLUS are here.

For less demanding applications, G.AL® C250 and G.AL® C210R are also widely used in cleanrooms

No matter which product you use, they all exhibit the following advantages:

- Low-stress

- Dimensional stability

- Excellent machinability

- Long-term temperature resistance 230°C

Need help finding the best solution for your project?

Interested in purchasing our products?

Just want to say hi?

Let us know with the button below, we’d love to connect with you!

More Topics

Electrochemical Aluminum Polishing

Electrochemical aluminum polishing is also known as electrolytic polishing, electrolytic smoothing, electrolytic brightening, or electropolishing.

5083 vs 6061 Aluminum

Comparing Properties, Strength, and Applications. Whether your project demands dimensional stability or structural strength, both 5083 and 6061 offer unique features to support a smoother production process.

Aluminum in Medical Technology

Aluminum in Medical Technology GLEICH's Role in Advanced Healthcare Solutions Aluminum plays a...