Classifying Wrought Aluminium Alloys

Understanding how to classify and work with aluminum alloys is essential for engineers, manufacturers, and buyers. Whether you’re sourcing aluminum rolled plates, flat bars, or precision cast plates, using the correct aluminum alloy classification ensures performance and safety. This guide explains the differences between wrought and cast aluminum, the EN AW and AA designation systems, and the key standards governing mechanical and chemical properties.

How Are Aluminum Semi-Finished Products Categorized?

Aluminum alloys are categorized into two main groups:

Aluminum Casting Alloys (AC)

Designated with “AC”, e.g., EN AC-51200 (EN AC AlMg9)

Optimized for mold-filling in molten form

Not suitable for mechanical forming

Wrought Aluminum Alloys (EN AW)

Designated with “AW”, e.g., EN AW-5754 (EN AW AlMg3)

Excellent for rolling, forging, and extrusion

Used in structural and machining applications

Are Cast Aluminum Plates Really Cast?

Understanding the Misnomer

Despite their name, commercial “cast plates” are made from wrought aluminum.

These products begin as billets and avoid the porosity issues common in true cast alloys.

Aluminum Alloy Classification Systems

(AA vs EN AW)

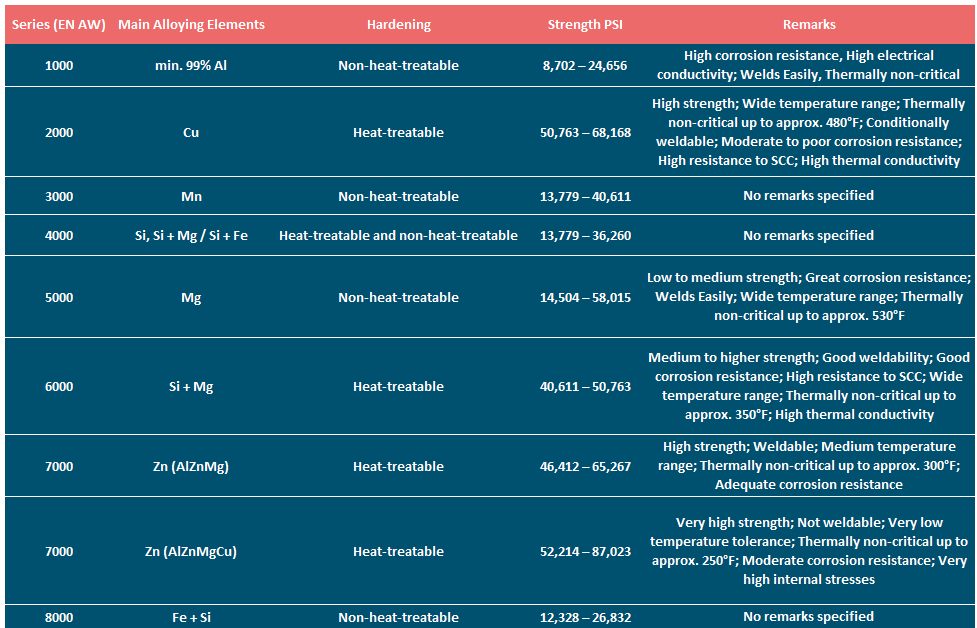

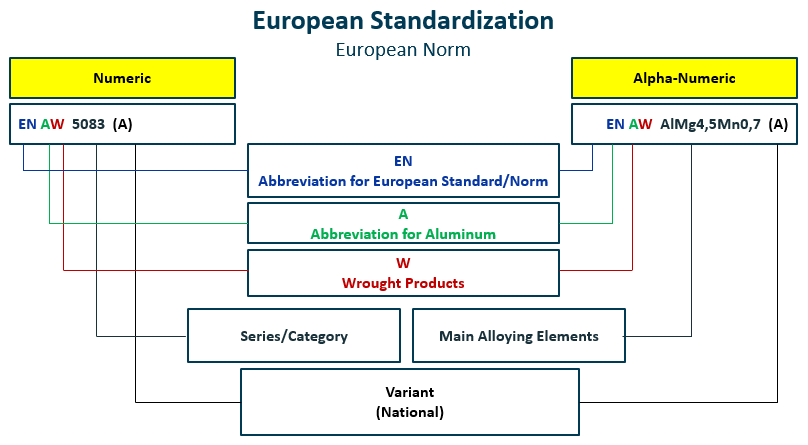

The Aluminum Association (AA) system organizes alloys from 1000 to 8000 by their principal alloying element. Europe adds an alphanumeric identifier (e.g., EN AW AlMg4.5Mn0.7) based on legacy DIN standards.

Special Note: 7000 Series Alloys

- AlZnMg: Welds easily, e.g., EN AW 7019

- AlZnMgCu: High-strength, not for use in welding, e.g., EN AW 7075

Aluminum Alloy Chemical Composition Standards (DIN EN 573-3)

DIN EN 573-3:2024 sets the minimum and maximum element limits for each alloy. GLEICH Aluminum further restricts these ranges in its G.AL® product line to ensure quality consistency.

*Europe adopted this system in the mid-1990s. They added an alphanumeric classification, derived from the old DIN 1725-1 system.

Aluminum Plate Mechanical Properties: What You Should Know

Minimum strengths for rolled, extruded, and drawn aluminum are defined in:

• DIN EN 485-2 – Sheets and plates

• DIN EN 754-2 – Drawn bars and tubes

• DIN EN 755-2 – Extruded profiles

Most values exceed minimums by 5–10%.

Why Don’t Cast Aluminum Plates Have Guaranteed Strengths?

Unlike wrought products, cast aluminum plates are only standardized by chemical composition. They lack guaranteed mechanical properties unless tested.

GLEICH Aluminum is the only global manufacturer that performs mechanical testing on every batch and issues EN 10204-3.1 certificates.

Aluminum Plate Tolerances: Thickness, Flatness & More

Thickness Tolerances

- Rolled Plates: Defined by DIN EN 485-3

- Cast Plates: GLEICH defines:

- Precision Cast: ±0.1 mm

- Raw/Mold ≤150 mm: -0/+2.5 mm

- Raw/Mold >150 mm: -0/+5 mm

- Precision Cast: ±0.1 mm

- Raw/Mold ≤150 mm: -0/+2.5 mm

- Raw/Mold >150 mm: -0/+5 mm

- Precision Cast: ±0.1 mm

- Raw/Mold ≤150 mm: -0/+2.5 mm

- Raw/Mold >150 mm: -0/+5 mm

Flatness Tolerances

- Rolled Plates: Based on DIN EN 485-3

- Cast Plates (G.AL® C250, ≤1570 mm width): 5 mm: 0.80 mm/m

6–12.7 mm: 0.40 mm/m >12.7 mm: 0.13 mm/m

- 5 mm: 0.80 mm/m

- 6–12.7 mm: 0.40 mm/m

- >12.7 mm: 0.13 mm/m

- Flatness is measured at 9 points, electronically recorded

- 5 mm: 0.80 mm/m

- 6–12.7 mm: 0.40 mm/m

- >12.7 mm: 0.13 mm/m

Looking for Certified Aluminum Cast Plates?

GLEICH Aluminum is the industry leader in precision aluminum cast plates, offering full traceability and mechanical certification. Contact us today for consistent quality and unmatched product safety with G.AL® plates.