Classifying Wrought Aluminum Alloys: Standards and Applications

Working with aluminum can be challenging—especially when it comes to classifying wrought aluminum alloys for semi-finished products like rolled plates, bars, and profiles. In this guide we explain the key differences between casting and wrought alloys, the designation systems (EN, AA, DIN), and their implications in fabrication, machining, and structural uses.

Understanding Aluminum Alloys

The differences between casting and wrought alloys

Aluminum Casting Alloys (AC)

Prefixed with “AC” (Aluminum Cast)

Example, EN AC-51200 (EN AC AlMg9).

“EN” denotes European Norm. Outside Europe the “EN” is usually dropped.

Casting alloys are specifically engineered to flow easily when molten, allowing them to completely and accurately fill complex mold shapes. Their primary strength lies in how well they perform in the liquid state — a property known as mold-filling capacity. While casting alloys are excellent at forming intricate shapes during casting, they cannot be reshaped once solidified, as they are not designed for deformation.

Wrought Aluminum Alloys (EN AW)

Prefixed with “AW” (Aluminum Wrought)

Example, EN AW-5754 (EN AW AlMg3).

“EN” stands for European Norm.

The key characteristic of wrought alloys is their excellent formability — they are well-suited to processes like rolling, forging, and extruding.

However, they are not suitable for producing cast aluminum parts, as they are not optimized for mold-filling in the molten state

Misconceptions: Are ‘Cast Plates’ Really Cast?

Many people think that all aluminum “cast plates” sold commercially are made from wrought alloys, but that’s not really the case. Some products that are called “cast plates” do use wrought alloy materials, but real cast plates are made from casting alloys—aluminum types specifically designed for casting. These alloys have properties that help them flow into complex mold shapes. Wrought alloys, on the other hand, are made to be reshaped using processes like rolling or forging, not casting. True cast plates and those made from wrought alloys can have very different mechanical properties, which is important when choosing the right material for a job.

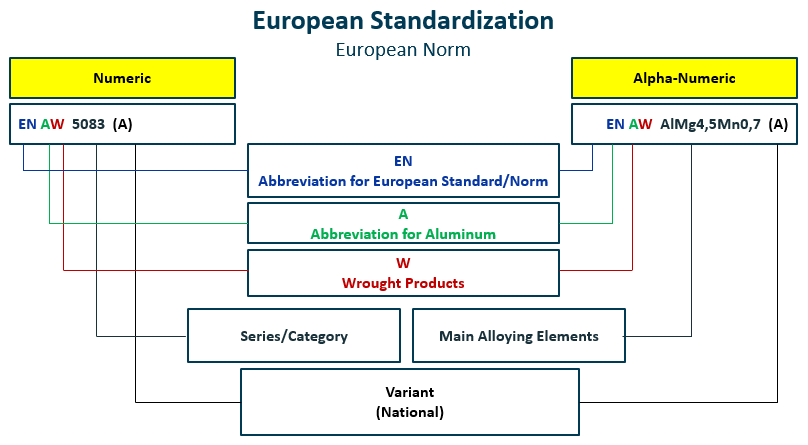

International Designation Systems for Aluminum Alloys

(AA vs EN AW)

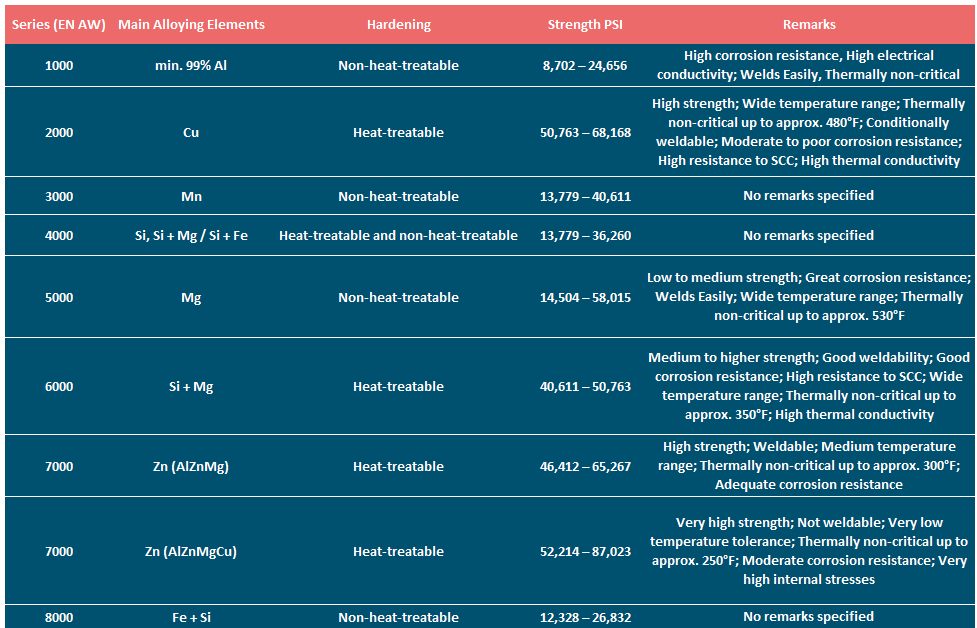

The Aluminum Association (AA) system from the U.S. organizes alloys in “Series” from 1000 to 8000 by their principal alloying element. This system was adopted globally with the exception of Russia, where they use GOST.

Europe adds an alphanumeric identifier (e.g., EN AW AlMg4.5Mn0.7) based on legacy DIN standards.

Europe adopted this system in the mid-1990s. They added an alphanumeric classification, derived from the old DIN 1725-1 system.

This alphanumeric system is only used in Europe and is not often used in North America or Asia.

With this European system, there can be two correct terms for one Aluminum alloy or semi-finished product.

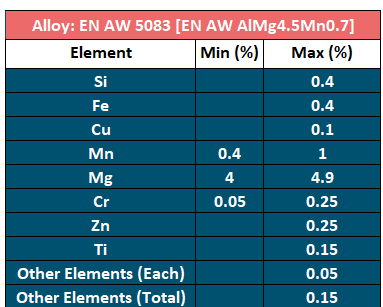

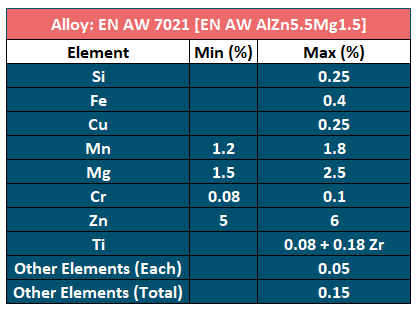

Aluminum Alloy Chemical Composition Standards (DIN EN 573-3)

According to the DIN EN 573-3:2024 standard, the minimum and maximum permitted contents of alloying elements can result in significant fluctuations in quality, strength, and technological properties between products made from different melt batches.

At GLEICH Aluminum, we apply even more strict internal specifications than those required by the standard. This ensures greater consistency, enhanced safety, and product reliability.

Examples of Chemical Composition

Mechanical Properties of Wrought Vs Cast Products

Minimum strengths for rolled, extruded, and drawn aluminum are defined in:

• DIN EN 485-2 – Sheets and plates

• DIN EN 754-2 – Drawn bars and tubes

• DIN EN 755-2 – Extruded profiles

Most values exceed minimums by 5–10%.

Why Don’t Cast Aluminum Plates Have Guaranteed Strengths?

Unlike wrought products, cast aluminum plates are only standardized by chemical composition. They lack guaranteed mechanical properties unless tested.

GLEICH Aluminum is the only global manufacturer that performs mechanical testing on every batch and issues EN 10204-3.1 certificates which guarantee the safety and strength for each product.

Note: For aluminum cast plates, strength values are typically referred to as “typical values.” For GLEICH aluminum products, this means that over 75% of all test samples fall within the values stated in our brochures.

Tolerances and Dimensional Accuracy

Industry Standards: Thickness Tolerances

Thickness Tolerances for Aluminum Rolled Plates

The thickness tolerance of aluminum rolled plates is defined in the standard DIN EN 485-3, which covers strips, sheets, and plates — limiting dimensions and shape tolerances for hot-rolled products.

These tolerances vary depending on the plate thickness and panel width.

Thickness Tolerances for Aluminum Cast Plates

Unlike rolled plates, the thickness tolerance and strength of aluminum cast plates are not governed by any official standard. Depending on the type—whether raw/molding or precision cast—each manufacturer defines their own quality specifications.

GLEICH Thickness Standards

At GLEICH, we have established the following thickness tolerances for G.AL® products:

- Precision casting plates: ±0.1 mm (approx. 0.004 Inches)

- Mold making/raw casting panels (up to 150 mm): -0/+2.5 mm (approx. 0.1 Inches)

- Mold making/raw casting boards (over 150 mm): -0/+5 mm (approx. 0.2 Inches)

Thickness measurements for G.AL® precision casting boards are conducted through automated processes, including electronic data collection and evaluation.

Industry Standards: Flatness Tolerances

Flatness tolerances for aluminum rolled plates

Flatness tolerances for aluminum rolled plates are regulated under DIN EN 485-3, which specifies tolerances based on plate thickness, width, and length. The “total deviation to length” refers to the rolling direction of the plate, while the “total deviation to width” is transverse to the rolling direction. These deviations apply only to entire panels; there is no guarantee of flatness for customer-specific cuts, and claims regarding the flatness of such cuts are not permitted.

Flatness tolerances for aluminum cast plates

Similar to thickness tolerances, flatness tolerances for aluminum cast plates are not subject to any standard. Each manufacturer sets their own quality standards based on the type of cast plate—raw/molding or precision casting.

GLEICH Flatness Standards

There may not be industry standards for cast plate tolerances, but that doesn’t mean we can’t enforce our own.

We have assigned the following flatness tolerances for G.AL® products:

Flatness Tolerances for G.AL® C250 Precision Casting Plates:

Width ≤ 1,570 mm (≤ 61.8 inches):

Thickness up to 5 mm (0.20 inches): 0.80 mm/m (approx. 0.03 inch/m)

Thickness 6-12.7 mm (0.24-0.50 inches): 0.40 mm/m (approx. 0.02 inch/m)

Thickness more than 12.7 mm (> 0.50 inches): 0.13 mm/m (approx. 0.005 inch/m)

Width > 1,570 mm (> 61.8 inches):

Thickness 10 mm (0.39 inches): No warranty

Flatness Tolerances for G.AL® C330:

Thickness up to 10 mm (0.39 inches): No warranty

Thickness 10-15 mm (0.39-0.59 inches): 0.40 mm/m (approx. 0.02 inch/m)

Thickness more than 15 mm (> 0.59 inches): 0.25 mm/m (approx. 0.01 inch/m)

Flatness Tolerances for G.AL® 7075 GF Precision Rolling Plates:

Thickness up to 12 mm (0.47 inches): No warranty

Thickness 12-15 mm (0.47-0.59 inches): 0.50 mm/m (approx. 0.02 inch/m)

Thickness more than 15 mm (> 0.59 inches): 0.25 mm/m (approx. 0.01 inch/m)

For raw or mold casting plates, flatness tolerances are not specified.

We measure the flatness of our G.AL® precision casting plates manually using a leveling gauge at nine points, with results recorded and evaluated electronically for accuracy.

We have established the following flatness tolerances for the following G.AL® products:

Flatness Tolerances for G.AL® C250 Precision Casting Plates:

Width ≤ 1,570 mm (≤ 61.8 inches):

Thickness 5 mm (0.20 inches): 0.80 mm/m (approx. 0.03 inches/m)

Thickness 6-12.7 mm (0.24-0.50 inches): 0.40 mm/m (approx. 0.016 inches/m)

Thickness > 12.7 mm (> 0.50 inches): 0.13 mm/m (approx. 0.005 inches/m)

Width > 1,570 mm (> 61.8 inches):

Thickness 10 mm (0.39 inches): No warranty

Flatness Tolerances for G.AL® C330:

Thickness 10 mm (0.39 inches): No warranty

Thickness 10-15 mm (0.39-0.59 inches): 0.40 mm/m (0.015 inches/m)

Thickness > 15 mm (> 0.59 inches): 0.25 mm/m (0.01 inches/m)

Flatness Tolerances for G.AL® 7075 GF Precision Rolling Plates:

Thickness 12 mm (0.47 inches): No warranty

Thickness 12-15 mm (0.47-0.59 inches): 0.50 mm/m (0.02 inch/m)

Thickness > 15 mm (> 0.59 inches): 0.25 mm/m (0.01 inch/m)

For raw or mold casting plates, flatness tolerances are not specified.

Looking for Certified Aluminum Cast Plates?

GLEICH is the industry leader in precision aluminum cast plates. We offer full traceability and mechanical certification. Contact us today for consistent quality and product safety with G.AL® plates.