G.AL® C250

Highest Precision, Lowest Tension

Medium-to-High-Strength Aluminum Cast Tool & Jig Plate

Medium to High Strength Cast Tool & Jig Plate

Alloy: EN AW-5083 [AlMg4.5Mn0.7 – 3,3547]

Type of alloy: Non heat-treatable

Temper: 03

Surface: Precision-milled on both sides, roughness Ra 0.4 µm, PVC-wrapped on both sides

- Precision-machined surface

- Consistent flatness

- Low internal stress

- Excellent corrosion resistance

- Homogeneous microstructure

- Medium to High strength

G.AL® C250 is GLEICH’s premium cast tool and jig plate, manufactured from EN AW-5083 aluminum alloy (AlMg4.5Mn0.7). We engineer each plate through our proprietary casting process and precise heat treatments to produce:

• A fine-grained, uniform structure

• Extremely low microporosity

• Superior dimensional stability

These plates offer enhanced anodizing properties, making them perfect for precision machining and visual elements.

Applications

Jigs & Fixtures

G.AL® C250’s outstanding stability and surface precision make it ideal for gauges, fixtures, and complex machined parts— often eliminating the need for additional surface work.

Semiconductors & Vacuums

G.AL® C250 offers low outgassing and strong vacuum compatibility. It performs reliably in clean environments, and the corrosion resistance ensures part longevity.

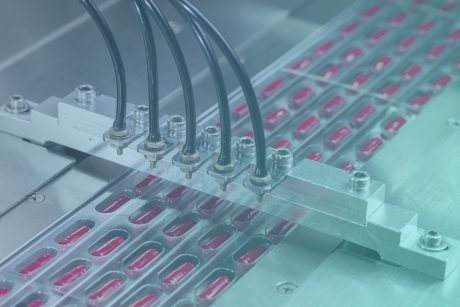

Packaging

Thanks to its anodizing capability, G.AL® C250 is ideal for support plates in packaging equipment where stability is critical and surface performance is a plus.

Automation & Motion Systems

Both rotary indexing tables (up to 2,160 mm in diameter) and coordinate plates can be produced without distortion, thanks to G.AL® C250‘s flatness and low internal stress.

Mechanical Engineering

Side and back panels, base plates, and precision-machined components can be manufactured quickly and cost-effectively—even when complex details and heavy machining are required.

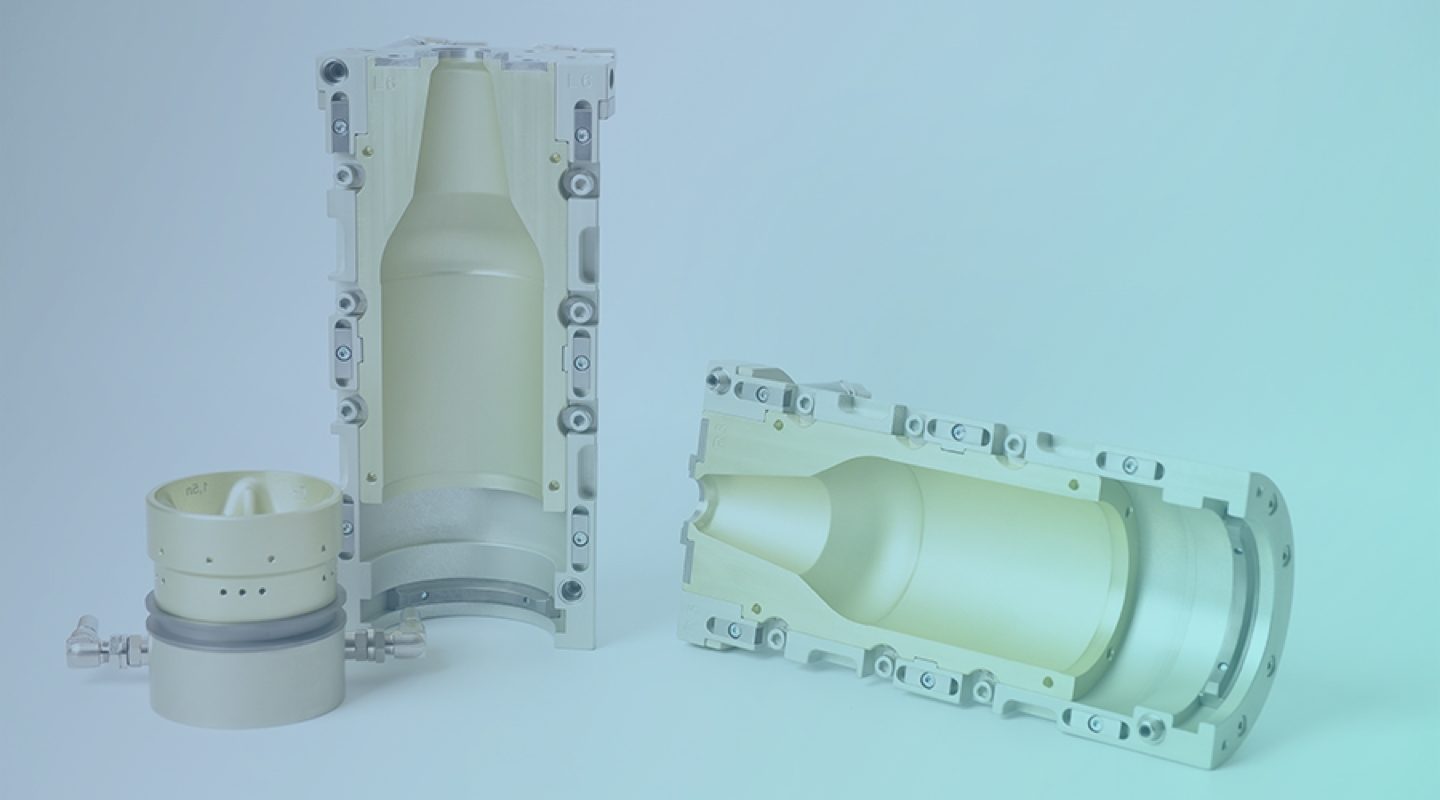

Model & Mold Making

G.AL® C250 is the go-to material for base and mounting plates in model and mold fabrication, offering excellent flatness, parallelism, and strength.

“To keep surface quality intact, avoid exposing the protective PVC film to sunlight. The natural rubber adhesive is not UV-resistant and will degrade in sunlight. This can make removal difficult and may damage the plate’s surface..”