G.AL® Sawn Plates

Stability at Extreme Cutting Degrees

If you need aluminum in any thicknesses with:

- Low Distortion

- Dimensional Stability

- Excellent Machinability

Then our G.AL® Sawn Plates are for you.

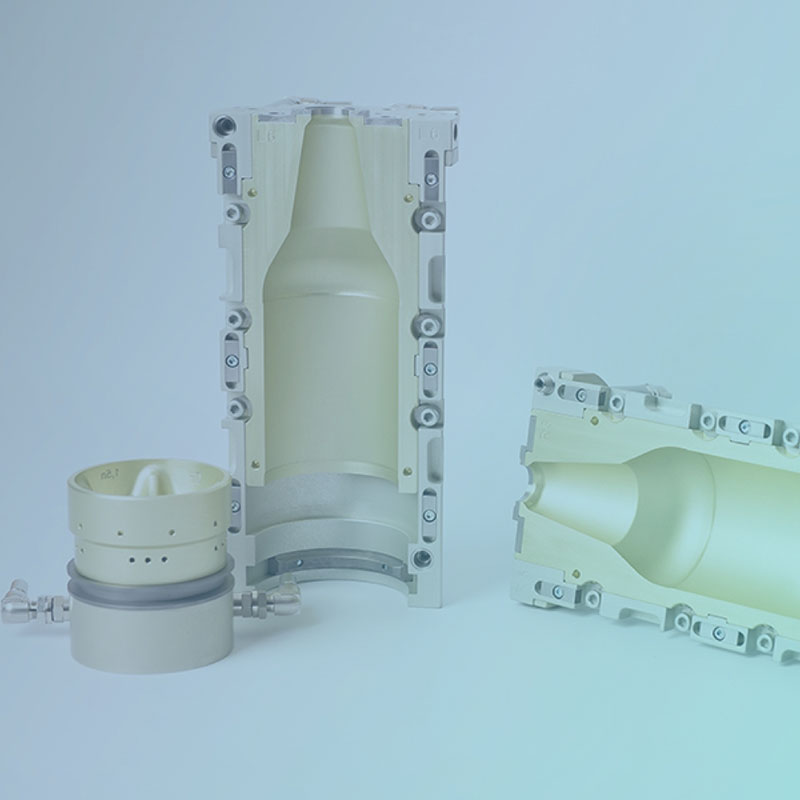

G.AL® sawn aluminum plates are part of the G.AL® Cast Plates product family. The difference between our Sawn and Precision plates lies in their surface. G.AL® Sawn Cast Plates are machined on all six sides, making them perfect for components that require extensive machining or further refinement as part of the production process.

G.AL® Sawn Plates

G.AL® C210R

Machined on all sides

Alloy EN AW 5083

Versatility for medium-strength applications

G.AL® C330R

High Strength

Machined on all sides

Alloy EN AW 7021

Low Stress

Dimensional Stability

Because G.AL® Sawn Aluminum Plates are often used in mold making, they are classified as mold plates.

The production of mold-making plates varies significantly based on the alloy and final thickness. For reshaped or rolled grades up to 12 inches thick, hardened plates are commonly used. As thickness increases, structural differences between the core and edges become more pronounced due to the limitations of the forming and rolling process, which prevents a uniform microstructure.

For applications requiring greater thickness, cast plates are usually the industry norm. However, traditional cast plates typically offer lower strength compared to other materials.

That’s why we developed a breakthrough solution: G.AL® C330R

a high-strength, heat-treatable cast plate designed specifically for mold making. Engineered to outperform existing options, it offers superior strength and processing capabilities. For even larger shapes, our G.AL® C210R mold-making cast plate is available in thicknesses up to 41.5 inches.